Death & Dismemberment

“You want me to do what?!” “And go WHERE?” “Are you serious?”

“COSTA RICA!”

I hung the phone up, still in shock.

This will be the first time, in thirty four years, that I have really ever written anything about the end days of Delta and its final disposition. As faithful reader knows I have spent the last year telling about the precious metals industry and how crazy it was. This story is based on fact, and, some filling in the blanks on my part, but based on very hard information left at Delta Smelting, as you will soon see.

The Death

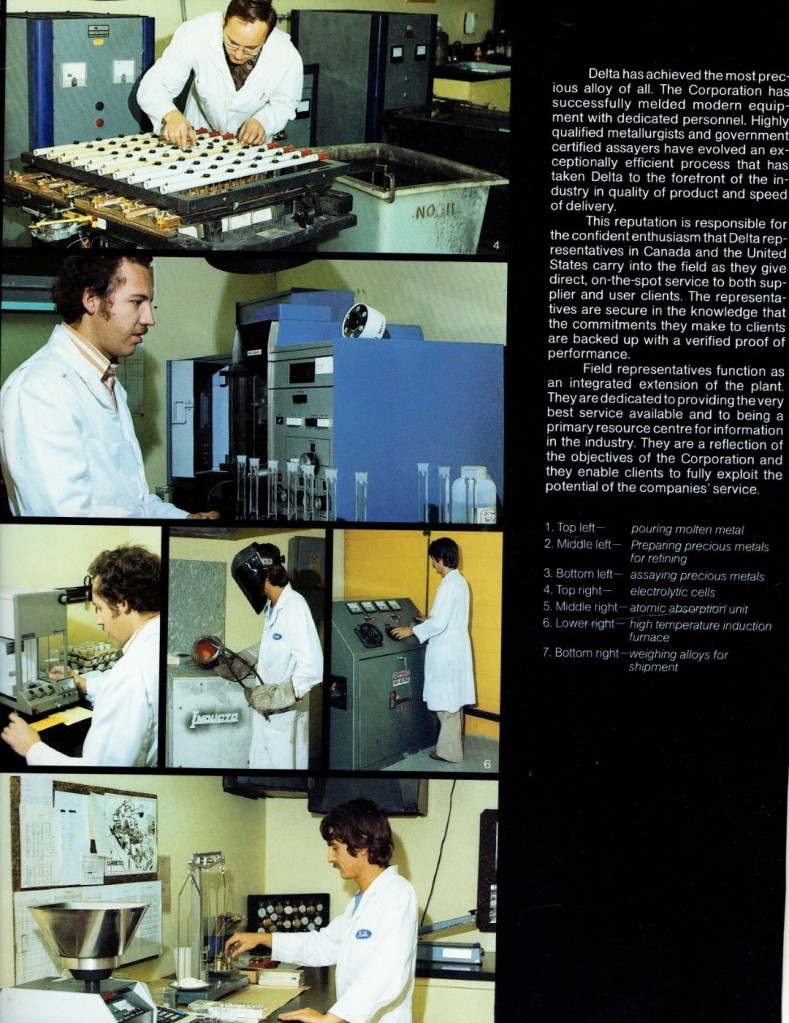

Delta was formed in 1966, but it was not until 1969/1970, when I started, that it became a precious metals refinery, basically servicing the large jewellery industry in Vancouver. Its beginning actually involved a scam, not on Delta’s part, as they were the victims, but to do with an ore process, that is maybe one final story to be told down the road.

When I started I was tasked with learning to make karat gold alloys for the jewellers, besides doing the actual refining. To this point the jewellers had to order from Toronto or the U.S., so a Western based refinery was off to a great start right from the doors opening. It did not take long with a small staff to build the business to a size that said we could look further for refining feed. This took the owner, Dave Seed, to head to the Yukon, to build the business with placer miners.

It was a very small crew of very dedicated people that built Delta up in a very short duration of time. We worked longs days, weekends, just to keep the refining process going, to insure a rapid turnaround of metal.

Long story short it was towards the end of the 70’s that a couple of us saw something going on that was NOT very good. It would serve no purpose at this point to go over it, but we presented the issue to the board of directors. The bottom line was they did nothing and that is when a few of us chose to leave and start our own company, WESSEX REFINING. Leaving Delta was one of

the harder decisions in my life at the time. Dave Seed was a personal family friend that went back to before he started Delta.

This time period is also when AJM Gold Refining was under construction, Engelhard was coming to the Province and Imperial Smelting had their office in Vancouver, serving the jewellery industry.

After we left Delta (1978/79), it continued at a frantic pace of growth. Just before I left I was pumping out hundreds of ounces a week of karat alloys into the Seattle market, with a return of scrap that had the refinery going 24/7. Delta was also opening an office in Los Angeles, a small one in Hawaii, and, starting to build a smelt facility in Fairbanks, Alaska. My friend from high school, who was hired as Delta’s 3rd employee, was tasked to run the Alaska operation. The price of metals was also going up in this time period, so that was starting to both cause a rush of people cashing in their old silver, and, the bullion bar investment market ramped up at a phenomenal rate.

My time at both Delta and Wessex was split between making casting alloys and pouring silver and gold bullion bars. I would say without question that I have made personally over 500,000 troz of silver bullion alone and tens of thousands of ounces of gold bullion bars. We could hardly keep up with the demand. Silver of course was predicted to go to $300.00 troz. Gold went from $35.00 troz to $850.00 troz USD, when Nixon took the U.S. off the gold standard in 1971. I can still remember our excitement when it went from $35.00 to $70.00 in 1972.

Delta had a staff by 1980 of close to 100 people and due to this massive increase in business, saw that it needed to expand. This was to be the beginning of its downfall.

As Delta filled up the building with people and had no more room for equipment, they conceived a plan to have a custom, all inclusive processing plant built. It could take ore in the back door and pump fine gold and silver products out the front. While the idea and concept was good, it was the pace that they tried to expand that was the problem. By the early 80’s they had staggering amounts of metal going through the plant. In one month alone they refined 100,000 troz of silver from scrap, photography and other sources. This was on top of the amount of both placer gold and jewellery scrap, which now was costing 850.00/troz USD, or close to 1,000.00 CDN for gold. This required HUGE cash flow to purchase the gold from miners and jewellers, wages, and run the plant, which was not a cheap proposition.

An English company was hired, TOLLTRECK ENGINEERING, to design the new building, which had been purchased not far from the existing plant. TOLLTRECK was to provide the complete flow sheet of equipment and supply said equipment, from a huge rotary furnace, down to electrolytic silver cells, the works so to speak. The first engineering PROPOSAL cost $250,000.00, no small amount of change in 1981.

Now, as Delta started to have a cash crunch, they started to realize that they did not have enough money to both operate and try to build this Rolls Royce of a plant. So, what do they do, they ask TOLLTRECK to downsize the plant! This of course cost more money, in a time when they could least afford it. We must remember that they had the Alaska operation up and running and while it was a standalone operation, DELTA Vancouver still had to purchase that gold. The first rounds of employee cutbacks happened and some 10% salary reductions!

DELTA also had started a pilot plant to refine mercury and silver from watch batteries, and, a plant to try to recover silver from spent film and x-ray plates. This required the renting of another ware house around the corner with the appropriate staff of trained chemists and lab people. Another expensive proposition.

The banks finally refused to lend any more money, so DELTA then asked TOLLTRECK to cut back on design size again, costing MORE money. This then caused more internal issues with employees, as there seemed to be no real sense of direction. At this point, the fall of 1981 to the spring of 1982, DELTA was some $1.8 million dollars in the hole.

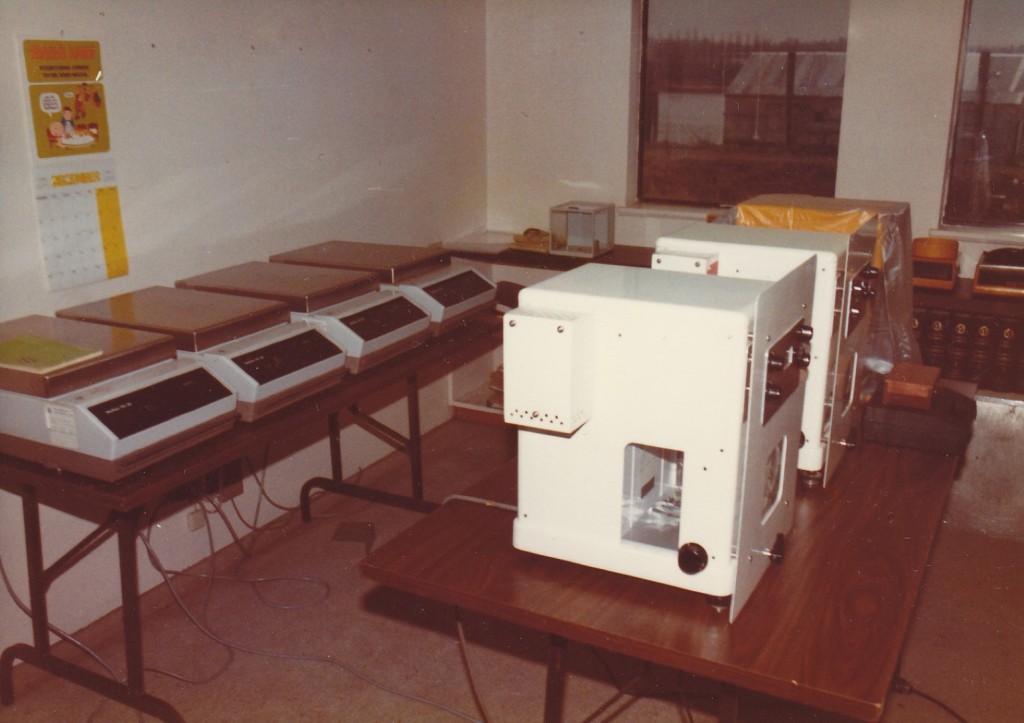

Through this time period two other things were going on. Delta decided it needed to jump into the computer world for accounting, a very new thing back then. A very expensive system was purchased, $250,400 CDN, a main-frame computer that filled a very large room upstairs. It too was a Rolls Royce in its time. Today’s smart phone, which fits in your hand, has twenty times the power of that computer. It brought its own issues of then needing computer people to program it, two were hired. Then as it turned out, it generated so much heat that the room had to be sealed and then it’s own air conditioning system had to be installed. Sealing was critical for both cleanliness and the fact that the air balance from all the exhaust and make up air fans running in the plant, screwed up the computer room. This cost a LOT of money.

Here is the final cruncher for DELTA and ultimately for the customers, especially the placer mining industry. DELTA came up with a scheme to offer to pay interest on metal left on deposit. At the time, DELTA was paying up to 14% on some metal accounts (Bank rate at the time was 11%) with an average of 6%, that added up to a lot of money, but, the kicker was that they then took that very metal on deposit and took it to the bank…and borrowed money against that, to try to keep operating. Then, in 1982, gold and silver dropped, so gold that they had paid $800.+ USD went down to $297.00 USD.

The final death knell came, really not known by very many people, is that a private safety deposit box company in Vancouver had a robbery on a weekend. Through circumstances that even I’m not clear on, a rumour got started that there was an issue at DELTA. This prompted some people to try to get their metal out of DELTA. Secondly, a local coin dealer went out of business and blamed an un-named precious metals refiner, who actually was in Calgary, for his financial problems. People thought it was DELTA, the perfect storm you could say. Due to production scheduling and fine metal allotment on any given day, it was not possible to suddenly hand over fine gold to an unannounced customer arriving at the door. Sure, you could pick it up in a week, but, this got construed as a stall tactic. It did not take long for the placer miner to talk to his fellow miner, which then had the snowball effect. Before you knew it, there was a monstrous run by people wanting their bullion back, or dollars, or BOTH! DELTA was in very serious trouble, with Dave Seed trying to appease people, the very miners that he had gone out into the field and gained their trust, who had left their metal, that it would be safe and SECURE.

An emergency meeting was held, trying to come up with a plan, but, that damage was beyond done, there was no way DELTA could fulfill its obligations. On April 14th, 1983 DELTA filed for a proposal under the bankruptcy act, to be put forth on May 4th, 1983.

The list of creditors was huge, the largest bankruptcy in B.C. at the time, 1,929 people and business’s owed money….$12.59 MILLION to be exact (over 26 Million today). I won’t go into the details of the proposal, as it involves pages of legalese but the bottom line was they wanted to pay back at cents on the dollar and take 6 years to clear everything. It was a sketchy plan at best and with no one willing to lend them more money…or give them metal….it was a done deal.

On May 4th the meeting was held at the Richmond Inn, with over 500 creditors showing up. To say the mood in the room was beyond angry is an understatement. As information came out, there turned out to be less than $500,000 worth of metal in the plant and “possible” liquidation value of only $454,000.00 for all the assets! That turned out to be so far from the truth it was a joke. Stay tuned.

The creditors voted DELTA into oblivion that day, with the R.C.M.P. looking into possible criminal charges. Some of the placer miners that I deal with today lost the most, one family losing over $400,000.00 CDN., another $300,000.00. To this day I still hear the anger in a few voices. Dave Seed had to basically go into hiding and the DELTA staff got tarred with the whole fiasco and they scattered to the four winds.

I had been temporarily re-hired by the AJM Gold Refinery, which had re-named itself PACIFIC REFINERIES.

I too was soon to be back unemployed…but not for long.

The Dismemberment

I picked up the ringing phone (ever notice how my stories start with a ringing phone…weird), listening to the voice on the other end. I hung up, rattled at what I have just been offered to do.

DELTA had now been in mothballs for over 9 months now. A company was hired to do a final clean up of some residual non-precious solutions and the fellow who ran the chemical part of the refinery (Ron Williams) was hired to do a final clean up on any precious metals solutions. Campbell Sharp Limited was the trustee, to look after the bankruptcy and attempt a final sale. The reality was that no one stepped up to buy the place, markets were down, AJM/PACIFIC refineries had blown up, WESSEX was gone, just leaving ENGELHARD, whom were new to the Province then.

Campbell Sharp tried the equivalent of a garage sale on the warehouse where the mercury and silver film equipment was, but that produced very little dollars. Refining equipment is very specialized and no market really existed. What ultimately happened is that Campbell Sharp sucked all the money that was left out of the coffers for the “administration” of the bankruptcy.

Remember I mentioned that DELTA purchased a new main-frame computer? Somehow a financial company in Toronto heard about the computer and that it was virtually brand new….they wanted it. An agreement was made with Campbell Sharp, where the Toronto Company purchased the WHOLE assets in the building for $100,000.00, which of course gave them the main-frame computer, a steal of a deal. At the same time, they had a business interest in Central America, which is what brings me back into the story.

They have somehow tracked me down and ask if I will undertake the dismantling of DELTA, clean up the equipment…and then take it to COSTA RICA to build a small gold refinery there!

I put the phone down, in shock. I was just laid off for the final time from AJM/PACIFIC, had a new baby daughter, and now was asked to enter into this project. I needed the work for sure, but, to go to COSTA RICA for 3 months was a tough decision to ponder. After much discussion with my wife, it was a go, as I could fly back for a few days each month.

In January of 1984 I was given the keys to the DELTA building.

Have you ever seen those post-apocalyptic movies, where one day everyone is going about their business, then, the next day they are GONE! This is what it was like walking into that building, cold, quiet, like a tomb. Almost everything was like it was when they walked out the door 9 months ago. It was weird. I guess that employees were told to grab their personal things and were marched out. I went room to room, not having been here for 5-6 years since I left. Desks still had coffee cups on them, the odd jacket still there, shoes, etc.

As I wandered the building, I started to see what a daunting project this was going to be. Part of my job was to also see about selling anything that would not go to Costa Rica. I had the help of two friends to give me a hand in taking the place apart.

First task was to inventory EVERYTHING, so over the coming few weeks we picked an office that would be a marshaling point for office related things, a room would be filled with calculators, one with scales, one with office supplies, etc.. I looked at the furnace room, deciding in which order the furnaces would be pulled from their position.

Now, while I am doing this, I am very aware of what precious metals might be left, having been involved in all aspects of where they might be lurking, from spills to boil over’s in the furnaces. I half jokingly said in my contract that if I found any “gold bars”, that that would be part of my pay….they agreed to that!

At the same time as we moved office supplies about I decided to make the gold solution precipitation room in the chemical refinery our sand blasting room. All the equipment had rusted quite badly and needed a spruce up; this would be the perfect room, not too big and it had a BIG fan to evacuate the dust. This turned out to be a blessing in disguise.

Each time we moved a desk, we would go through it, which is where the true picture of what happened to DELTA was really revealed. Each person got a memo of course, but, as I worked my way literally to the office of President Dave Seed, there were those memo’s that were for managements eyes ONLY. This is where I started to see the plans and other things that led to the downfall. I put all memos into a box, which I still have to this day. It is too bad that the R.C.M.P. and the investigators did not do this very thing, as it would have filled in so much information right from the start.

Another thing that we found was money, change, loose bills; I think we ended up with around two hundred dollars by the time we went through 50 desks. We basically ended up with the equivalent of a small Staples store in office supplies and gear. To this day I have never had to purchase a pencil, graph paper, etc.. I ended up with a nice desk which I am sitting at as I type this.

I decided to take the gold and silver reactor deck apart first. This was done so I could BURN it. The furnace room had a “crematoria”, something that I had helped put together before I left DELTA. It let us burn jewellers sweeps and at the time, carbon recovery material, that gold mines used. The deck would have trace gold and silver solutions soaked into it so the plan was to render anything and everything that could be melted, to see what we could recover. The reactors would also be the first to be dismantled and cleaned, ready for shipment.

In the furnace room we started to chisel out some of the furnaces, the floors first. This is where any gold or silver would be. The furnaces would be re-lined in Costa Rica, as no sense in shipping the weight of a fully intact furnace; they needed re-building anyhow. All surviving crucibles got flushed out with an appropriate flux.

One day I went into the silver recovery cartridge room. Back in the days of film, both consumer, movie, x-ray, newspapers and the like, silver was used on those films and plates. During the development process, silver is washed off that film into solution. That solution then would pass through a KODAK recovery cartridge, basically a 5 gallon bucket filled with steel wool. An ion exchange would occur, with the silver coming out of solution and the iron going into solution. Once these cartridges had no more iron left, they would be sent for refining. This was a horrible job, as the 5 gallon buckets would have to be opened, the remaining solution drained, then, the sludge would be poured into a large tray, and then those trays put into an oven for drying. It was messy and it smelled of sulphur. I was going to move the drying oven, which was like a baker’s oven. I disconnected the gas and vent lines, then rocked the oven to see how heavy it might be and if I would need a hand. As I rocked the oven up on one side…I realized that it seemed to be recessed into the floor….but that would not be right. As I looked close I realized that I had NOT been walking on a concrete floor, but, a 1” thick carpet of spilled sludge over the years. This should be interesting I thought, knowing full well that the sludge would have silver in it. Our first melt the next day produced a silver bar of virtually 100 troz!

It took us two weeks to dismantle the reactor deck, as six reactors, all the steam piping and fragile glass ware just had to be handled carefully so as to not break any of the glass. We cut the wooden deck up and slowly fed it into the crematoria, taking all of three days to burn it all down to ash. That produced a small gold/silver button when melted.

All the while we had our sand blasting room up and running, the three of us taking turns as the “blaster.” Every bullion mold, pouring tong, grinder, jaw crusher, etc, got cleaned, blasted with sand and then painted. We had segregated the equipment that was to be shipped and had another area where we could have a garage sale so to speak. Other things really were just scrap value.

We were now into our second month of dismantling the place, having sold some office equipment, some of the tools from the maintenance room and other bits and pieces.

One day, as I was working in the furnace room, the building started to rumble and shake, and then a few seconds later a tremendous banging and crashing upstairs occurred, followed by a huge snap as a circuit breaker tripped. What the heck was that? I ran upstairs, into the fan room above our sandblasting room. There as a cloud of rusty dust billowing out the door. What had happened was that after years of gold laden acid fumes having gone up that piping and into the fan, then it sat for 9 months of damp moisture, was, it had finally suffered catastrophic failure and exploded. I let the dust settle and proceeded to check it out, with the realization hitting me that this dust would contain GOLD! Suffice to say I scrapped every bit of material out of the fan and the piping, making sure I cleaned the inside of the fan housing and blades. What a windfall when I melted all that!

As I left the upstairs fan area, I also noticed a brown wooden case tucked away in a far corner, it had FRAGILE stickers on it. What treasure might this be? I had one of the other guys come and give me a hand to take it downstairs to our clean office area. The lid was well fastened so it took me 5 minutes to undo all the screws. What was it you ask….It was a beautiful antique assay balance, the Rolls Royce of its time, made in the U.S. in the 20’s, that I actually used when we bought it from an old assay lab that closed down in Vancouver in 1971! This scale would have assayed a huge amount from the mines of B.C. in the 1920’s – 1960’s. DELTA had tried sending it back to the manufacturer for refurbishing, but, the cost would exceed the newer digital scales that were starting to come out. DELTA had wanted to send it to the new Alaska operation. It was sent back from the manufacture and sat in this case till I found it. It is now on display as part of my mining collection.

I would get phone calls weekly from the Toronto people, seeing how things were going. At the end of February my contact said there were some issues with the Costa Rican government, not elaborating, but just that things might be put on hold. We had sold most bits and pieces, had all things destined for a small refinery ready to go.

In the middle of March the Toronto head business man came out to Vancouver, to give us the bad news. It turned out that the Costa Rican government, and officials at the time, wanted a lot of money under the table so to speak, to expedite permits, some customs issues and a few other things. The financial company wanted no part of that and pulled out of the deal. Here we go I thought, insanity again in the precious metals world. We were tasked at that point to try to sell off everything that was left. I bought some equipment, as I knew some places where I could re-sell. Engelhard came and bought some reactors and sent them back to Toronto, but, as it turned out, they too had suffered from the down turn in metals and decided to NOT finish the new plant they had built in Tillbury Industrial Park in Delta, B.C..

By April of 1984 DELTA was gutted, what was left gone into storage in Burnaby, where it ultimately went to scrap. DELTA marched on into history, a bitter memory for a lot of miners and jewellers and while it had been a hard decision for me at the time, I’m so glad I did leave.

In the middle of April, 1984, I got another phone call………ENGELHARD and the other person who had left DELTA to start WESSEX with me, needed a qualified melter. On April 24, 1984 I started with ENGELHARD, where I basically am to this day. Engelhard died in the year 2000, but as my office here has always done well financially, as service and HONESTY has been our priority, TECHNIC purchased our office and continues on.

There was no money left to go back to anyone, the Trustees sucked it all up in administration fees. Dave and his Dad, Harry Seed went to court, charged with Criminal Code violations under the Fraudulent Acts sections, but, it was not proven that there was criminal INTENT. The judgment was…and I quote from the Law Digest of B.C., April 30, 1986…

“The defendants were relatively unsophisticated business men with poor management skills and they had been prey to a superficial scheme suggested by others”

Tell that to all the miners and jewellers that lost 12 MILLION DOLLARS……

Keith Law

February 20, 2017

Post Script:

When I started this story some two weeks ago, I must admit that I thought I would have to dig deep to write about more in this Industry. What I did find, as I did my fact checking on dates, etc, to do with Delta, that I have this box of all the things that have blown up in this Industry. In there, which I should have remembered, was the terrible saga of INTERNATIONAL NESMONT Industrial Gold refiners who were found to have brass bars in their vaults. Then there was JAMES METALURGICAL SERVICES INC., another huge scam. GOLDEN WEST REFINING went down when HANDY & HARMON in the U.S. got caught doing some bad stuff. In the U.S. METALOR USA REFINING CORP. Had to pay a huge fine for illegal financial transactions

These companies all were here on the lower mainland, makes you wonder if there was something in the air that brought out the worst in people.

So…it looks like you’re stuck for awhile with me…if you get bored, just let me know.

Awesome write up and look forward for more. Thank you.

LikeLike

So glad it resonated with people on this wonderful site.

I have many stories I have written over the years, some to do with the scams perpetrated on people involving gold out of Africa and other such things. I also will send a couple of my stories of the aspect of the actual refining of gold, as done at Delta/Wessex. Then, some of the accidents, one of which led to the fire that Delta suffered in Nov of 1973. I do not know how far off topic my stories are from the root of this site, so I will let the moderator decide.

As I write for a newsletter also, I have been formulating my next story, which will talk about the real world frenzy that happened when the metal markets climbed…and then the FLOOD of silver (and gold) that came out of the woodwork, and I mean FLOOD. You cannot visualize how much silver scrap, on a daily basis, waited at our door. Most of the bars on this site very much came from sterling silver, as that silver went directly to anodes and then to the silver cells to make pure silver crystals, then to bars.

In this story will be a few “sad” episodes, as I had to tell people their so called silver/gold…was NOT! One story, that I remember so vividly, was that of three guys that showed up one day with a TRUCK LOAD OF GOLD….I will say no more at this point.

LikeLike

I look forward to hearing this sorry about the “Truck Load of Gold” that came in. We appreciate your contributions, Keith!

LikeLike

That was a great article! wow.. so much detail! Thanks for sharing!!

PK

LikeLike

Glad yo enjoyed it. Thanks for the feedback.

LikeLike

Yes, thank you for your comment. I have written many stories about my time in the precious metals world, but, have actually had not much feed back, due to the nature of the Newsletter I write for, people scattered all over British Columbia.

So thank you to all on this forum that took the time to read and send a comment.

I have basically put together a book, with pictures, of my 49 years in the Industry. More for my family while I can remember all this, but, when I step back and read the whole thing, WOW…it was crazy!!!

As I have a publication date for my next story for the Mining newsletter, I will also drop it here. It is about the insane time of the scrap coming in, in quantities you cannot imagine….ON A DAILY BASIS. A lot of sad parts, and some truly funny ones. This will also tie in that most of the silver bars ( at least Delta bars) came right from mostly BIRKS and other fine English manufacturers, and HOW that happened ( the refining process).

Till then,

Keith Law

LikeLike

Good days, I remember the first day I started, you and I seemed to hit it off, will never forget the black tusk and the oil furnace cooking my car in the garage where you used to winter store the Datsun 510

LikeLike

JEEZ…..Paul……We were talking about you the other day and the garage. Yes, I remember the oil heater with the stuck carburetor. So luck we got there when we did, it could have burned that garage down. Sure warm inside though…ha..ha! I was also telling of how much work it was to change that clutch in your TR-6.

I have a 1973 Datsun 510 that I still drive, 300HP, it’s a monster.

I have been writing and have made a book about the precious metals years here in B.C.. Not many people left, I was the last to be employed in that hay day of refining. I still see my friend Evan, whom you may remember went to run the smelter in Fairbanks for Delta. He was there when Delta blew up! So sad as he got tarred with the fallout from that, even though he had no participation in it.

Love to talk,

Keith

LikeLike