Thanks to Keith for sharing more stories in this post about his time at Delta. These stories are amazing for our readers to live vicariously through those in the thick of the refining business in the golden age of silver. Ok, enough from me!

FORWARD

It was in 2015 that I wrote this story, being in the middle of documenting the companies and other things that went on in

the refining Industry in B.C..

My friend Evan (2nd employee) and I would often reminisce

about what we went through…and SURVIVED.

You have to realize, we did everything in those early days, wiring, gas pipe fitting, re-building furnaces, plumbing, and maintenance! Very rarely did we call trades in, can you imagine doing all that now….doing self taught 3 phase wiring….ha.

We also worked with a ton of very dangerous chemicals, nitric acid, hydrochloric acid, sulphuric acid, alcohol, ammonia. We used the extremely dangerous hydrofluoric acid to clean gold nuggets. Our dry chemicals for melting were Borax anhydrous, dense soda ash, potassium nitrate and a few others goodies, not good to breathe. The mercury refining alone presented some serious concerns for processing.

When Delta moved to the new building, all that was behind us,

my world became the alloys and investment bars totally. But, we both learned skill sets that stayed with us, being able to stay safe as the years went by.

And at that, a lesson would occasionally remind us of how quickly something can go bad. We had poured a new lid for one of the smaller furnaces, likely weighing close to 200 lbs. We had set it in place, which meant the lid pivot pipe had been slid down onto the receiving pipe, fastened to the furnace body. The process was to SLOWLY increase the heat to begin the drying process, which normally takes a day of running. The lid was left 1” up from the furnace body. Anyone of us would watch for any sign of steam, then shut the heat off till it stopped steaming, re-fire and repeat. That was to continue all day till we felt we could go full throttle with heat.

About an hour after starting the furnace, I was in my alloy room and Evan was in the silver room. A tremendous BOOM and then heavy crash was heard from the furnace room. We both arrived at the same time. The lid had exploded, a “steam spall”, blowing the lid up off the pipe and throwing itself across the room. Scary if anyone had been in there. There was high temp cement everywhere, the lid ruined. To think the force required to fire that 200 lbs of cement and steel across the room….WOW!

We could only think that there was a large air pocket that got trapped during the lid cast and for whatever reason did not get out. In subsequent rebuilds, we would use our small jackhammer as a vibrator, like the concrete industry does, to get those bubbles out. We had to teach ourselves the best water/cement mix to use on this 3,000 F refractory cement.

So, we did survive, our arms do show the years of small radiant heat burns, even through our safety clothing. We learned to touch NOTHING till we checked if it was hot or not. Dave Seed’s brother came into the furnace room one day, spying a nice gold bar I had just poured and bumped out, before I could say anything, he grabbed the bar…….

Read on for the early days on Shell Road, before moving to Cambie Road….

Keith Law

Aug 30, 2023

I thought as a shift from the scam stories, I would write about the beginning days of the precious metals refining business in B.C., and my personal experience of …….

WHEN THINGS GO WRONG

In a blink of bright orange flame and an ear ringing explosion, the white, five gallon plastic bucket ceased to exist in its present form.

Lets step back a minute here, it’s the early 70’s, in a brand new industry on the West Coast. There were two of us to start, as the original employees, in our early 20’s. Then, after a few years, we hired some graduating chemistry students from B.C.I.T. . Now imagine you have access to all sorts of wonderful chemicals and gasses that can go BOOM! What 20 year old would not think that was a dream come true?

Over those early years I had to experiment with different cover gases during the pouring process for bullion bars. I was in charge of all the bullion production at that time and as the markets started rise, so did sales of investment products, mainly silver. This was the start of the silver rush culminating in the HUNT BROTHERS

(https://en.wikipedia.org/wiki/Silver_Thursday)

getting caught in their speculation and the market grenading into oblivion.

I had come up with a mix of argon and hydrogen gas, to be played over the surface of the cooling bar, giving it a nice, finished looking surface. Now, hydrogen burns with a bright orange flame and in a confined space, under the right conditions, it will explode. Our young 20 year old minds thought it would be cool to see how HIGH we could launch a 5 gallon plastic bucket if we filled it with hydrogen. Our first refinery was in an undeveloped area of Richmond, where we had no neighbours to annoy, although over time we got on a first name basis with some of the Richmond fire department personnel…more on that later.

So imagine 3 of us standing outside, with a 5 gallon white plastic bucket turned upside down and a line running from our hydrogen bottle, with a tap on the end. We gave it a shot of hydrogen, and of course hydrogen being lighter than air, it would have gone to the top of the bucket. Harry, who was a smoker, had a lit cigarette hooked at the end of a straightened out coat hanger. He gently pushed it under the lip of the bucket and in a second or two there was a small WHUMP and the bucket maybe went 2 feet in the air. COOL! Ok, so we need more hydrogen, operating under the principle: if some is good…more is better! Another good shot of hydrogen, repeat procedure, WHUMP, bucket goes maybe 4 feet in the air. Right, so we now think we need to really fill this thing up. Our objective is to try to get the bucket to fly as high as our vault, some 15 feet high. I turn the tap on, letting the gas run for 15 seconds or so. I step back…good thing, as Harry stretches his arm out, with the lit cigarette, trying to be as far away as possible. Just as the glowing end of the cigarette got close to the edge of the bucket..KABOOM…think the Hindenburg here, a monstrous orange flame, an ear ringing explosion, the white plastic bucket did not go up so much as it just seemed to disappear into a million white shards of plastic shrapnel, blowing the 3 of us off our feet, and singeing all the hair on Harry’s face. That was the last time we tried that little experiment.

As we had a complete lab, I think we had most of the chemicals required to make some very dangerous things. At the time, we were developing a copper recovery system, doing mercury refining and slowly trying to figure out how to get the silver out of silver oxide batteries.

In line with that one day it came upon us that we could make a pressure sensitive explosive in small quantities. It required a certain chemical to be filtered over iodine crystals and then left to dry. We would sprinkle the crystals on the floor, then, jump on them. There would be a small BANG and a little cloud of purple gas would come up. We thought that was hysterical. We had gotten to the point that we had hired a secretary/bookkeeper. The office she worked in was some 50 feet from the washroom, with a concrete floor in between. Someone…not me…came up with the brilliant idea to sprinkle a trail of crystals from the office to the washroom, so when the secretary came out…..

She came out of the office in her high heels, thus having an even greater pressure on the crystals, due to the small contact area. The first little bang had her confused as to what happened, then another, then another, all with greater clouds of purple gas. She started to run to the washroom…BAD idea…bang’s went to small booms, then a staccato, of small explosions, all accompanied by an ever increasing cloud of purple gas. We of course were in hysterics, but the language coming out of the washroom was not to be forgotten, and the threat of physical harm had us putting that little joke away!

On a more serious note, things did go bad over time. We had a couple of people who had no sense of safety, leading to some serious accidents, our first being an accident with nitric acid by our assayer, Barry. He just seemed plain accident prone, lighting the gas assay furnace after the gas had run too long before an actual flame was applied. He blew the door off the assay muffle furnace a few times; luckily he was not in front of it. I had to put my foot down and tell him he was not allowed to start the furnace, one of us would.

One morning, he had to re-fill a nitric acid bottle from a keg of nitric, which for you to imagine is basically a beer keg size. There was a small hand pump in the drum, with a spigot that curved down to fill a bottle. He went to the drum WITHOUT his safety shield on, only his glasses. He must have been in a bit of a rush and gave the pump a faster pull and push. The spigot blew off and he got a full stroke of nitric acid right in his face. I was in the lab at the time and all I heard was a scream, then he came running though the door to the lab. His face, hair and shoulders were smoking, white fumes just boiling off him. Think of every horror movie you may have seen. One thing I have been blessed with my whole life is the ability to think fast on my feet. I grabbed him and dragged him to our lab sink, pushing his head down while I turned the tap on. My partner ripped Barry’s shirt off, which was soaked in nitric, still cooking his neck and shoulders. I was worried about drowning him!

As Richmond was still very small then, I decided I would rush him to the hospital, as getting an ambulance then would just have taken too long. I was just getting into car racing then and had a very high performance oriented car, so we threw him into my passenger seat and off we went. I must have been doing around 80 MPH on Westminster Highway when an RCMP car hits his lights behind me…for speeding. I climb on the brakes and stop, he comes over, obviously ready to give me a ticket, I say; “Industrial accident, with acid!” He took one look at Barry and says: “Follow me!” I did the last 2 miles with a police escort.

Barry survived with minimal face scarring, which is a miracle. His glasses saved his eyes and his reflex action had his eye lids closed, so only they got some burning. His neck and ears got scarred, as the shirt held the nitric against his skin. As we all had long hair on the early 70’s, the hair over his ears also held the nitric in, burning the tips severely. I shudder to think what he would have looked like if that sink had not been so close.

His final accident, before he quit, was he put a ladder up against the wall of the lab. He wanted to go up on the sub-ceiling to check our water still. He had the base of the ladder likely 8 feet away from the wall, so you know that is not going to work. Just as he got to the top of the ladder, some 8 feet up, the ladder base just kicked out, and he slid down the wall, screaming all the way. His hands of course are clutching the sides of the ladder, so when it hit the ground, it both knocked the wind out of him and PINCHED his fingers to the floor. It took two of us to lift him up, so we could free his hands, then, pumped his legs to get his lungs going. His legacy was the two ladder grooves down our gyp rock wall board. We felt bad for him but, it was hard not to laugh on that one.

Our other problem employee was Bevan, a walking accident, as his brain was not all in gear at times. Water…water and moisture, the most dangerous situations in a melt facility can be caused by plain old water. As Bevan was to find out the first time, it can cause a LOT of pain also. As we were silver refiners, we would take the impure silver dore bars and pour them into anodes, to go into the electrolytic cells. As the anodes wore down, there would be a piece left that could not contact the solution, so it would get re-melted. These “anode heads” of course were wet from the tank solution. We were all made aware of how dangerous it could be to ADD, wet material to molten metal. One day, Bevan was pouring anodes, a three person job. I would run the overhead crane buttons, which lifted the crucible out of the furnace, then, Bevan and another person would tip the crucible holding cradle, to do the pour. There would always be some molten silver left in the crucible, then, more impure metal was added, which was SUPPOSED to be dry. Bevan thought he could get away with adding some anode heads, which as it turned out were wet. I could not tell with my dark green face shield on. We were about to have a major lesson on what a steam spall is.

Imagine two people standing about 5 feet apart, facing each other, with the silver crucible in between the middle of them. I am standing just behind Bevan, with the crane control in my hand. Bevan reaches to the bucket with the anode heads and grabs a large handful, then drops them into the crucible. There is a huge snapping sound and then a blast that both goes straight up out of the crucible, and, BLOWS a hole in the side of the crucible, directly at Bevan’s groin, hitting him like a shot gun charge, with molten silver particles. He of course reels backwards, knocking me down and the two of us end up a heap on the floor. He is yelling in pain like crazy, gets up and runs to the washroom to drop his pants and check out the damage. The other fellow is ducking falling fluorescent bulb glass, as the ejection upward has blown out the lights. This “small” detail will haunt Bevan in his next episode. The blast hit him right in the groin, burning holes in his jeans and leaving small burns on every bit of skin, even the private parts, in a one foot radius. He hurt for a month over that stupid move. We were all lucky it was not worse.

We had a large 500 gallon tank, which held our “end” solutions, for final treatment. This involved lowering a 2 foot diameter aluminum disc into the solution, and the chemical reaction would precipitate out the last of the metals. During this process hydrogen was generated as an “off” gas. One day, as Bevan was walking by, he decided to throw his lit cigarette into the top of the tank. WHUMP…the hydrogen lit right away, and, as the gas was continually evolving, it started to burn like lightning bolts IN the solution, cracking and thumping away. I heard the first whump and went to see what was going on, finding Bevan in a panic as he realized…HOW DO WE PUT THIS OUT!!!!!????? What the hell was he thinking? I was afraid we would have a major fire, as the odd gas ball ignited in the air, well above the fluid surface. Fortunately, we had a lid for the tank, stored in the back of the plant. I ran like hell and grabbed it, and like any fire, once it was starved for air, it went out.

In this time period, we had the Richmond fire department come, twice due to people driving down Highway 99 and as we had the blast furnace room door open, they thought the place was on fire, as the glow from the furnace was very bright at night and could be seen from the highway.

The third time was again when Bevan, a chemistry graduate from BCIT, decided it would be interesting to throw some old sodium metal into the ditch next to the plant. Sodium reacts VIOLENTLY with water, so as soon as it hit the water, it exploded, setting the dry grass on fire between the ditch and the railway tracks, and I mean exploded! We grabbed our hose but it just did not have the volume of water to do anything. So, the fire department was called! At least Bevan got a real dressing down from the fire guys for that one, another really stupid move. At this point the owner of the company was finally seeing there was an issue with this guy, but, it took one more MAJOR incident to rein him in.

You would have thought he would have learned from the crucible explosion, but, it turns out not. We used to work late at times, as the furnaces would be hot, so we could keep some of the processes going well into the evening.

One day, around dinner, my good friend and I were working in the lab. Bevan and Doug were doing a pour in our smaller furnace room. I heard a pop, then a bang, and the sound of falling glass. Again, it turns out Bevan had added damp metal to a pour, which exploded straight up, taking out the lights. We ran out to see what had happened, looking up at the roof. We could see nothing going on and after taking another strip off Bevan, I left for dinner at Pizza Hut, along with my friend. Bevan and Doug said they would stay for another 20 minutes, just to make sure there were no issues up on the ceiling.

Evan and I were sitting in the Pizza Hut, which is on Westminster Highway, about 5 miles from work. As we were just finishing up, we heard fire engines coming and they blew by the dinner. I kid you not, I said to Evan, “Wouldn’t that be funny if they were heading to the plant, hah, hah!”

We left and as we came up over the Cambie Road over pass, I could see 50 feet of flame coming out of the roof of our plant! We were on fire! I blasted into the driveway, just as the fire guys were busting through the door, hoses in hand. The furnace room area was fully engulfed in flame. One of the fire guys grabbed me and asked me to point out any dangerous things, like acid containers, gas bottles, etc.. Here I was getting dragged through the door, a wall of flame in front of me..Holy Mother of God….

As I pointed out some of the things, he just let loose with the hose, blowing stuff to oblivion with the pressure, as he wet it down. He broke at lot of stuff that the fire would not have damaged. As I went back out the door to the parking lot, the roof collapsed, and as it did that, it broke the gas line. Now we have a huge blow torch on the ceiling. This really got the fire guys attention! There was a massive scramble to get to the gas meter, to try to shut the main off. The fire guys needed to eat more Wheaties, as they could not get it to move. In the next few seconds the company owner screams into the lot and blasts out of his car. He was a very strong guy, and grabs a section of pipe from the scrap we had, slides it over the gas valve lever, and shuts the blow torch off. Meanwhile, the guys with the hoses have started to get things wet downed, the tar and gravel roof being the hardest, which has now collapsed into the furnace room floor, with the tar spewing clouds of black smoke.

In the aftermath, we could only think that either a molten drop of silver sat up on the trusses, smoldering away, or, there was a slow electrical short from the lights getting blown out. Either way, something got going up on the ceiling, starting the fire. The lab survived, as did our chemical section of the refinery, other than some glass ware that was hit by the fire hoses. That was November 20th, 1973.

As our neighbour next door had just moved out, the timing could not have been better, as we had run out of space in our existing facility. Within 3 weeks we had moved our furnaces over to that space and other than some smoke and water damage, the lab and refinery were able to keep going. I ended up with a nice new office, so I was quite happy. The fire was deemed and accident, yet at the same time, it was Bevan’s careless work ethic that caused it.

Ultimately, even I ended up having a very bad accident, more from lack of experience I guess. I had worked in a sawmill, on a tug, ran a hay machine, construction, built fibreglass boats, etc. . I was always aware of moving machinery, tools that could rip your hand off, stuff like that.

One day, in 1973, we had to rebuild our large, tilting, oil fired blast furnace. This required the furnace to be rotated on its’ side. The lid, which weighed some 220 lbs, is swung up and held in position by a steel pin. The crucible is carefully removed from its base. Then, we would start to chisel away at the floor, using a long steel bar to hammer away at the base and the floor, to remove the worn refractory.

What happened next, I can only surmise? At some point, the vibration and impact from the hammering must have let the lid shift away from the so called safety pin. My upper body was leaning into the opening of the furnace. The lid swung down and either it, or the steel bar, whacked the side of my head and jaw. I remember nothing, as apparently I walked into the lab, sat down on a chair and was pure white. I just sat there. The guys called for an ambulance and I was rushed to Vancouver General, where it was deemed I had gotten hit and had a major concussion, to the point that I had total amnesia. While my jaw was not broken, it was kind of dislocated and that would haunt me later into my 40’s when it turned out I had a ton of hairline fractures in my rear molars, causing me all sorts of dental issues. I knew my name, but that was it. The nurse kept checking on me, asking me what had happened. All I apparently could say was that I knew that something happened as I was in the hospital. It took about 4 days, when familiar faces would show up, that things slowly came back. In looking at what happened, I can only think that I heard the lid slip from the pin and was starting to pull myself out of the opening of the furnace, so I only got a glancing blow. If my full head and body had been in there, I either would have been decapitated or just crushed. That was my life time warning shot for sure. Anytime I did or do anything, I take a really good look at the situation…FIRST! That lid should have been chained up in place.

Over the years we got wiser and smarter and our hiring policy became one of people with a real mechanical sense and situational awareness, as a gold and silver melt and refinery facility is a very dangerous environment.

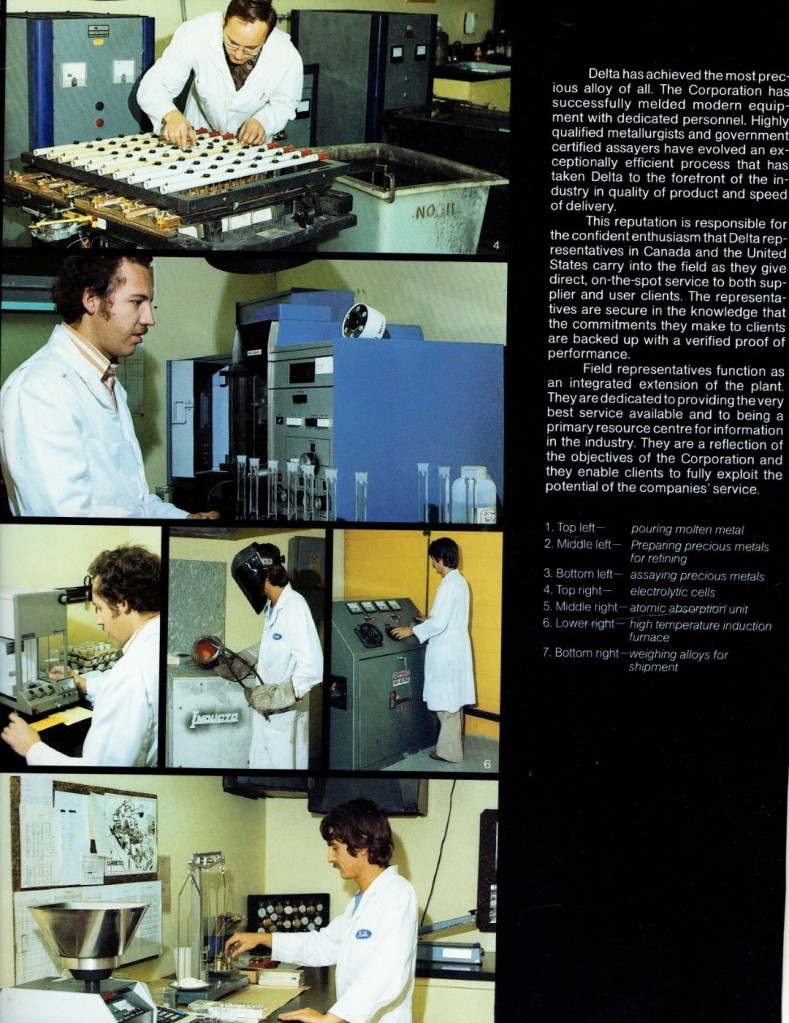

As I wrote this story, it brought back a lot of memories, good and bad, of an industry I helped develop here on the West Coast. I taught myself to melt and refine gold and silver, to pure product, then take that pure material and make it into bullion investment products and jewellery casting alloys. At one point my alloys supplied all of Vancouver, Seattle, and we were starting to get into the Los Angeles market at the time, no mean feat. In that time period, we started to develop the placer mining business, as the miners were more than happy to deal with a west coast business, and not have to deal with eastern Canada.

To this day, the placer mining industry is our mainstay.

Keith Law

October 23, 2015

Next issue…the largest scam I have ever seen!!!!